Botou RH Die Casting Co., Ltd. is a large-scale joint-stock company engaged in die casting and processing, located in the famous "Lion City" of Cangzhou City in China. The company was founded in 2008 and later regrouped in 2016. Since its inception, the company has focused on the production of high-quality die casting products that meet their customers' needs.

Die casting is a widely accepted manufacturing process preferred over other manufacturing processes due to its high-quality results and ease of manufacturing. Die casting is a process that produces a variety of products and components used in different industries. The process involves the use of metals, specifically zinc, aluminum, and magnesium. Zinc die casting is popular among manufacturers because of its many benefits.

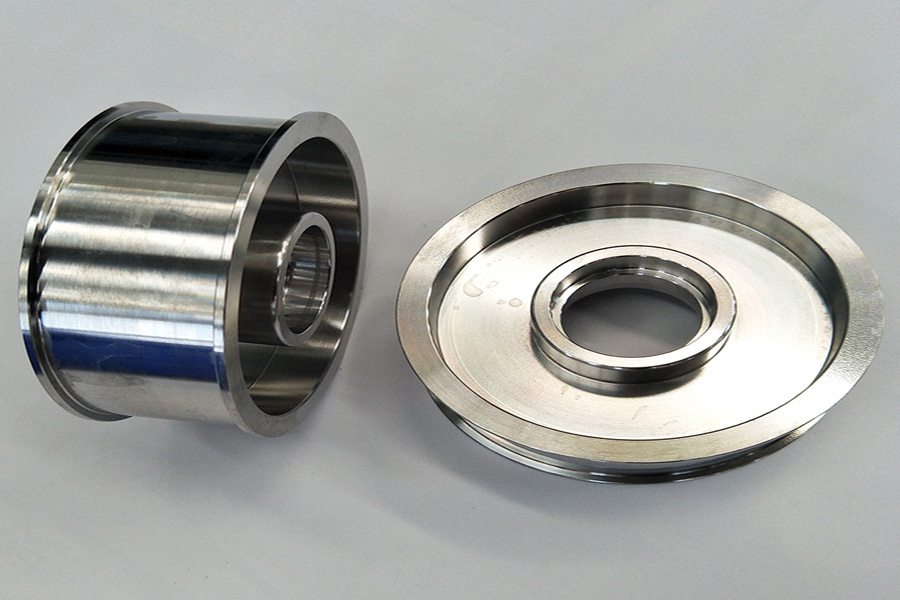

The use of zinc alloy in die casting is common because it has unmatched properties such as high corrosion resistance, high strength, good thermal conductivity, and dimensional accuracy. When die casting with zinc, it is possible to produce products with thin walls with complex shapes and close dimensional tolerances. The excellent flowability of the metal also enables precise reproduction of fine details.

Benefits of Zinc Alloy Die Casting

Zinc alloy die casting offers many advantages, making it one of the most sought-after manufacturing processes in the industry. Below are some of the benefits of using zinc for die casting:

1. Low melting point: The melting point of zinc is one of the lowest among all metals, making it easier to melt and die cast. This reduces energy costs, making it a cost-effective process.

2. High strength: Zinc has excellent strength properties compared to other metals such as aluminum. It also has high ductility and impact resistance, making it an ideal choice for manufacturing components that require high strength.

3. Corrosion resistance: Zinc has excellent corrosion resistance, making it ideal for outdoor applications where weather can be a factor. Zinc die cast products can withstand harsh weather conditions and corrosive substances.

4. High precision: The excellent flowability of zinc allows for the production of products with high precision, complex shapes, and dimensionally accurate walls.

Applications of Zinc Alloy Die Casting

The versatility of zinc die casting allows its use in various industries. Below are some of the applications of zinc alloy die casting:

1. Automotive Industry: The automotive industry is one of the largest users of zinc die casting. Zinc alloy die casting is used for making various components such as door handles, seat adjusters, gearshift handles, and brake system components.

2. Electrical Industry: Zinc die casting is used to make electrical components such as connectors, adapters, switches, and housings. Zinc also has excellent electrical conductivity, making it ideal for electrical applications.

3. Consumer Goods Industry: Zinc is used to make various consumer goods such as zippers, buckles, and handles. The excellent corrosion resistance of zinc makes it ideal for these applications.

4. Medical Industry: Zinc is popular in the medical industry due to its antimicrobial properties. Zinc die casting is used to create antimicrobial door handles, bed rails, and other components used in medical facilities.

Conclusion

Zinc alloy die casting is a popular manufacturing process that offers numerous advantages over other manufacturing processes. The excellent properties of zinc make it an ideal choice for the production of high-quality products. Botou RH Die Casting Co., Ltd. is a leading provider of high-quality zinc die cast products. They are committed to producing products that meet their customers' needs and are proud to be one of the top companies in the industry. Whether it is the automotive industry, electrical industry, or consumer goods industry, zinc die casting has become an integral part of the manufacturing process.