In contrast to gravity die casting, where gravity is used to fill the mold, pressure die casting relies on hydraulic or pneumatic pressure to force the metal into the mold. This allows for more complex shapes and thinner walls, as well as faster cycle times and higher production rates. Pressure die casting can be used to produce a wide range of metal parts, from tiny components to large automotive parts and aerospace components.

The process of pressure die casting begins with the preparation of the mold. The mold is usually made of hardened steel or other durable materials, and it consists of two halves that fit together to create a cavity in the desired shape of the part. The mold is then coated with a release agent to facilitate the removal of the finished casting.

Next, the molten metal is prepared in a furnace or other melting device. The metal is heated to its melting point and held at that temperature until it is ready to be cast. The molten metal is then transferred to a shot chamber, where it is injected into the mold at high pressure.

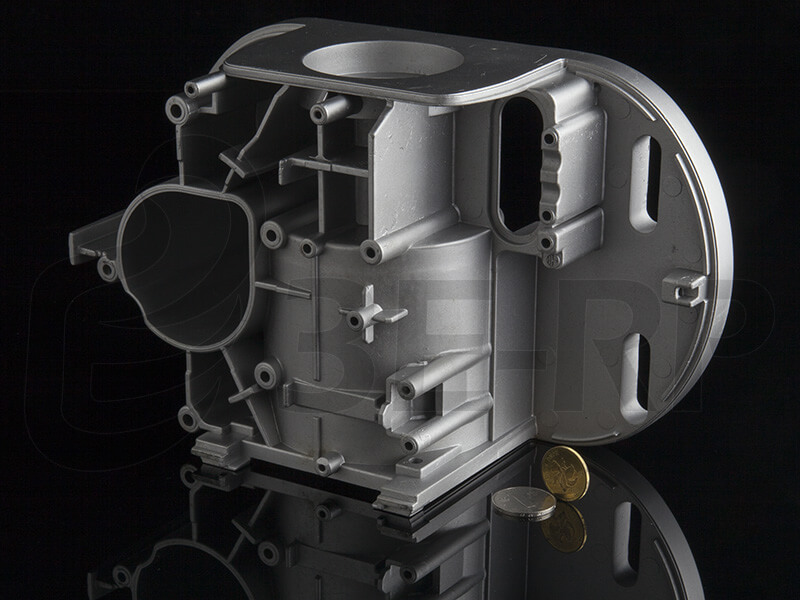

Once the mold is filled, the metal cools and solidifies quickly, forming a solid casting in the shape of the mold cavity. The mold is then opened and the casting is removed, typically by an ejector system that pushes the casting out of the mold. The casting may then be cleaned and finished as desired, often through processes such as machining, polishing, or coating.

Pressure die casting offers numerous advantages over other casting methods, including high accuracy, excellent surface finish, and the ability to produce complex shapes and thin walls. It is also a highly automated process, allowing for high production rates and consistent quality. However, pressure die casting can be more expensive than other casting methods, due to the need for specialized equipment and tooling.

In summary, pressure die casting is an effective and efficient method for producing high-quality metal castings with intricate shapes and structures. It offers numerous advantages over other casting methods and is used in a wide range of industries, from automotive and aerospace to electronics and consumer goods. By understanding the differences between pressure die casting and other casting methods, manufacturers can choose the best approach for their specific needs and applications.